| Screw Thread d | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M20 | ||||

| P | Pitch | Coarse thread | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | ||

| Fine thread-1 | / | / | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 1.5 | ||||

| Fine thread-2 | / | / | / | 1 | 1.25 | / | / | / | ||||

| b | L≤125 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 46 | |||

| 125<L≤200 | / | / | 28 | 32 | 36 | 40 | 44 | 52 | ||||

| L>200 | / | / | / | / | / | / | 57 | 65 | ||||

| c | min | 1 | 1.1 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | |||

| da | Form A | max | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 22.4 | ||

| Form B | max | 6.2 | 7.4 | 10 | 12.6 | 15.2 | 17.7 | 20.7 | 25.7 | |||

| dc | max | 11.8 | 14.2 | 18 | 22.3 | 26.6 | 30.5 | 35 | 43 | |||

| ds | max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | |||

| min | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 19.67 | ||||

| du | max | 5.5 | 6.6 | 9 | 11 | 13.5 | 15.5 | 17.5 | 22 | |||

| dw | min | 9.8 | 12.2 | 15.8 | 19.6 | 23.8 | 27.6 | 31.9 | 39.9 | |||

| e | min | 8.71 | 10.95 | 14.26 | 16.5 | 17.62 | 19.86 | 23.15 | 29.87 | |||

| f | max | 1.4 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | |||

| k | max | 5.4 | 6.6 | 8.1 | 9.2 | 11.5 | 12.8 | 14.4 | 17.1 | |||

| k1 | min | 2 | 2.5 | 3.2 | 3.6 | 4.6 | 5.1 | 5.8 | 6.8 | |||

| r1 | min | 0.25 | 0.4 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.8 | |||

| r2 | max | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.9 | 1 | 1.2 | |||

| r3 | min | 0.1 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | |||

| r4 | ≈ | 3 | 3.4 | 4.3 | 4.3 | 6.4 | 6.4 | 6.4 | 8.5 | |||

| s | max=nominal size | 8 | 10 | 13 | 15 | 16 | 18 | 21 | 27 | |||

| min | 7.78 | 9.78 | 12.73 | 14.73 | 15.73 | 17.73 | 20.67 | 26.67 | ||||

| t | max | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.45 | 0.5 | 0.65 | |||

| min | 0.05 | 0.05 | 0.1 | 0.15 | 0.15 | 0.2 | 0.25 | 0.3 | ||||

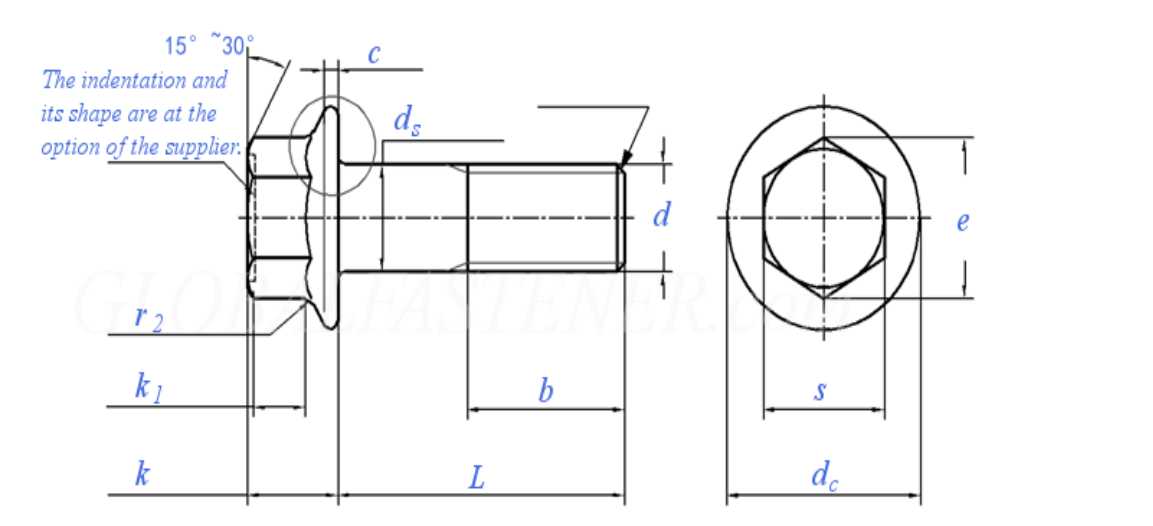

Flange bolt is a fastener with a little self-locking function. There is a round flange face under the hexagon head of a standard hexagon bolt. This flange face is not separated, but integrated with the hexagon head. There is an embossing groove under the flange face, which is used to generate strong friction with the matrix, so as to achieve the anti loosening function. Of course, there are also plane designs below the flange face, which are purchased according to the actual needs of users.

There are two materials used to produce flange bolts, one is carbon steel, the other is stainless steel. If it is a carbon steel flange bolt, it is also divided into three grades: 4.8, 8.8 and 10.9. Grade 4.8 flange bolt is made of Q235, and the surface shall be galvanized after production. Grade 8.8 flange bolt material is made of 35 steel, which requires heat treatment in the later stage, and the surface is oxidized and blackened or galvanized. The flange bolt material of grade 10.9 is made of alloy steel. Except that the automobile industry will use the flange bolt of grade 10.9, few other industries will use it. Stainless steel flange bolts are made of either SUS304 or SUS316 materials. Generally speaking, SUS304 stainless steel flange bolts are too many, and SUS316 materials are rarely used.

There are three types of hexagon flange bolt heads, one is flat hexagon flange bolt, that is to say, its hexagon head is the same as our commonly used hexagon bolt, but it has an additional flange face. This kind of flat head hexagon flange bolt has a higher grade, which can reach Grade 8.8 or 10.9. The other is the socket head flange bolt. The center of its hexagon head is not flat, but slightly concave. The material of this flange bolt is ordinary, and the level is only 4.8. Why are you so different? In fact, the meaning of concave is not the need of design, but such a shape does not require high requirements for the mold, and the equipment does not need too much tapping. In short, it is low cost and convenient for production. The other is that there is a cross slot in the center of the hexagon head, which can be installed with a hexagon wrench or a cross screwdriver. Generally, in the sinking position, when the wrench cannot operate, the cross screwdriver can be used to solve the problem.

Hexagon flange bolts, like common fasteners, are widely used. Flange bolts shall be made into blanks by cold pier equipment of 20 tons at one time, and shall be delivered to users after multiple processes such as tooth rolling, cleaning, testing and packaging. The surfaces of hexagon flange bolts galvanized with carbon steel are all environmentally-friendly galvanized. The thread go no go gauge inspection is qualified, and the ROHS report can be provided. At present, only SUS304 material is provided for stainless steel flange bolts, while ordinary stainless steel materials and 316 stainless steel flange bolts are not produced at present.

We often encounter users using unconventional stainless steel flange bolts, but in this case, it is difficult to supply, because the mold development and production of flange bolts are relatively difficult, which requires the mold to double click the cold pier to form. If it is a half tooth, the step forming of the rod also needs an opening and closing mold to complete: